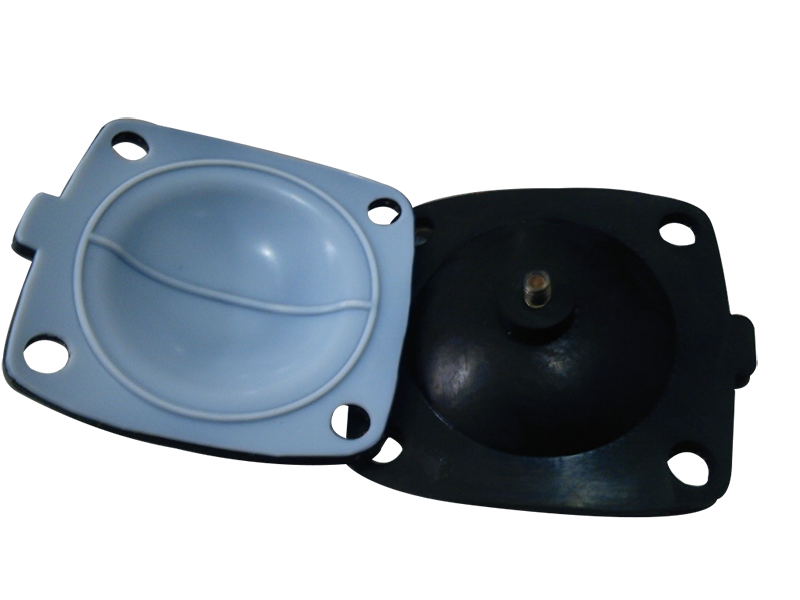

18 Years Factory High Temperature Teflon Seal Gasket - PTFE Coated Rubber Pump Diaphragm – Lucky Star Seal Detail:

Specifications:

Item:PTFE Coated Rubber Pump Diaphragm

Color:White

Material: PTFE,rubber

Size: OEM with drawings

Weigth: 0.5~500g

Property:

1.Best precision:0.1mm

2.Surface: flat and tidy,no defects of crevices layers and separation

3.Temperature range:-196℃ ~ 260℃

4.Chemical property:

A. aging resistance

B. radiation resistance

C. low permeability

D. high pressure resistance

E. oil resistance

F. anti-corrosion

Applications:

1.Sealing

2.Bushing

3.Medical device components

4.Electrical components

5. Pump and valve components

6.Food processing machinery components

Services:

1. Prompt delivery and consider services

2. Competitive price and high quality promise

3. ISO9000:2008/QS9000/SGS approved

4. OEM&ODM accepted

5. Rich experience in the design and manufacturing in PTFE adhered rubber seals.

Product detail pictures:

Related Product Guide:

PTFE Ring Gaskets – A Reliable Solution For The Engaging Industries

What Is A PTFE Ring Gasket?

Our primary intention should be to offer our clientele a serious and responsible enterprise relationship, delivering personalized attention to all of them for 18 Years Factory High Temperature Teflon Seal Gasket - PTFE Coated Rubber Pump Diaphragm – Lucky Star Seal, The product will supply to all over the world, such as: California , Algeria , Albania , So We also continuously function. we, focuse on high quality, and are conscious of the importance of environmental protection, most of the merchandise are pollution-free, environmentally friendly solutions, reuse on the solution. We've Updated our catalog, which introduces our organization. n detail and covers the primary products we provide at present, You may also visit our web-site, which involves our most recent product line. We look forward to reactivating our company connection.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.